The RDF (Refuse Derived Fuel) plant, part of the Hiriya Recycling Park, was officially inaugurated in 2017 after a one-year trial period. RDF refers to a fuel product made from waste—solid fuel derived from non-recyclable, high-calorific waste materials.

The RDF facility processes approximately 2,000 tons of mixed municipal solid waste (MSW) daily. The waste is sorted into organic materials, metals, and high-calorific dry waste, which is then transformed into solid fuel for the cement industry. On average, the plant produces 500 tons of RDF fuel each day. Waste sorting is performed with full control from a central monitoring system, using advanced mechanical and optical technologies with minimal human contact.

This state-of-the-art RDF plant is the result of a partnership between the Dan Region Association of Towns for Sanitation, Nesher Cement in Ramla, and Veridis, a leading environmental infrastructure company in Israel. The plant’s construction cost approximately 400 million NIS.

RDF: An Eco-Friendly Alternative Fuel

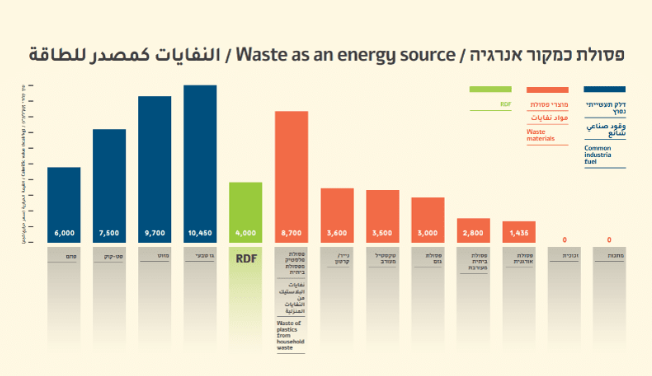

RDF serves as a sustainable alternative to fossil fuels derived from petroleum. The sorting process at the plant is designed to remove high-moisture organic components and metals with negligible caloric value early in the process. This increases the average caloric value of the remaining waste.

The remaining dry waste—primarily plastics, textiles, and paper/cardboard residues—has high energy content. While not suitable for recycling, these materials are ideal for use as alternative fuel. The RDF mixture produced at the Hiriya facility is tailored to meet the specific needs of the Nesher cement plant in Ramla, where the fuel is used in cement kilns.

To ensure suitability for cement production, the dry waste undergoes advanced sorting using optical separators to detect and remove waste containing PVC (polyvinyl chloride) and residual organic matter. The sorted mixture is then shredded into 15–20 mm particles. Continuous lab testing monitors the fuel’s energy content and moisture levels, confirming a calorific value exceeding 4,000 kcal/kg.

Nesher is Israel’s largest cement manufacturer and one of the country’s biggest energy consumers. Until 2010, the cement kilns operated almost entirely on petroleum coke (petcoke), a fuel derived from crude oil refining. In the past decade, Nesher has actively pursued alternative energy sources, including municipal waste.

Thanks to the advanced RDF facility and its collaboration with the Dan Region Association, Nesher has significantly reduced its reliance on fossil fuels. From the plant’s launch through the end of 2024, approximately 600,000 tons of RDF have been delivered to Nesher, avoiding landfill and replacing 15–20% of fossil fuel use in the cement kilns.

Since 2022, with the addition of a fourth sorting line, the RDF plant is equipped to handle up to 600,000 tons of mixed municipal waste per year. Around 85% of this is household mixed waste, while the remaining 15% includes light commercial-industrial waste and residue from the packaging sorting system operated by the Israeli EPR company Tamir.

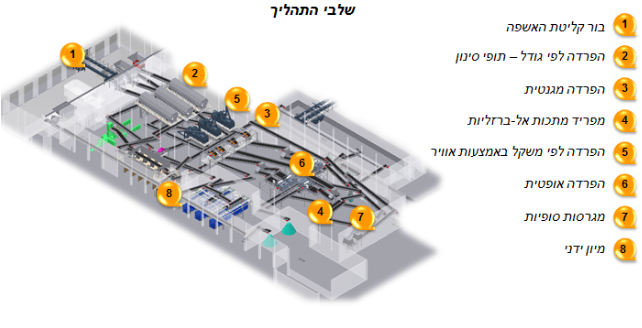

RDF Plant – Waste Sorting Process

Step 1 – Waste Preparation: Waste is unloaded into a receiving pit, shredded, and bags are opened. The prepared material is fed into sorting lines.

Step 2 – Size Separation: Trommel screens separate waste by size. Smaller items, mostly organic-biological materials, exit the main sorting line and are sent for composting after metal removal. In a complementary facility, additional screening removes non-organic residues (plastics, cardboard, etc.), and the organic material is biologically stabilized and converted to compost.

Step 3 – Density Separation: Air separators sort light from heavy waste materials. Lightweight items such as plastic bags and others continue through the process, while heavy components are removed and landfilled after metal recovery.

Step 4 – Metal Sorting: Ferrous metals are extracted using a powerful magnet. Non-ferrous metals, such as aluminum, are removed using eddy current separators.

Step 5 – Optical Sorting: Waste is scanned with infrared sensors on a conveyor belt. Based on light reflection, undesired materials—such as items containing PVC—are identified and removed. Optical sorting distinguishes materials based on density, thickness, and chemical composition.

Step 6 – Final Shredding: Dry waste is shredded into homogeneous 15–25 mm flakes, creating the final RDF product.

Waste Destinations After Sorting

- Recyclable metals (2%–5%) are sold to recycling facilities across Israel.

- Organic waste (35%–40%) is transferred to composting plants.

- Remaining dry waste (20%–30%) is shredded and transported by dedicated trucks to the Nesher cement plant in Ramla.

- Residual waste is sent to regulated landfills in southern Israel.